Reference Library

Pocket Watch Jewel Setting Types

Jewels are hard minerals added to the mechanics of the watch to prevent wear at pivot and collision points. Jewels must to fitted with precision, and any misalignment could potentially cause the watch to run improperly.

Pictured: A closeup of a metal bushing.

Bushing (Not Jeweled)

Metal bushings were used as a cheap alternative to jeweling. The pivots rotate in a hole drilled into the metal rather than in jewels. Metal bushings are found on cheaper movements and are more susceptible to wear.

Identification: The plate is not jeweled or only jeweled on some pivots.

Pictured: A closeup of a burnished jewel setting.

Burnished

Friction jewels are carefully pressed or burnished into the holes of the movement plate using special tools. The fit is tight enough to hold the jewels in place permanently. Friction jeweling requires fewer parts and less time than screw-set jewels. As a result, friction jewels were commonly fitted into movements of lower quaility. This trend held true until modern jeweling methods were adopted. Friction jewels are also more difficult to replace if cracked or broken.

Identification: The plate jewels do not have screws adjacent to the setting.

Pictured: A closeup of a faux jewel setting.

Faux Jewel Setting

Faux jewel settings appear to be screw set jewels. However, a closer inspection reveals that the circle around the jewel is simply engaved on the plate and the jewel is burnished directly. This type of jeweling increases the visual appeal of the watch and is typically seen on eleven-jewel movements where the pillar plate is not jeweled.

Identification: The circle around the jewel is engraved and the plate gilding texture continues into the area.

Pictured: A closeup of a friction jewel setting.

Friction Setting

Friction settings are pressed directly into the plate or bridges without being secured with screws.

Identification: The jewels feature a true setting, and the setting is not fitted with screws.

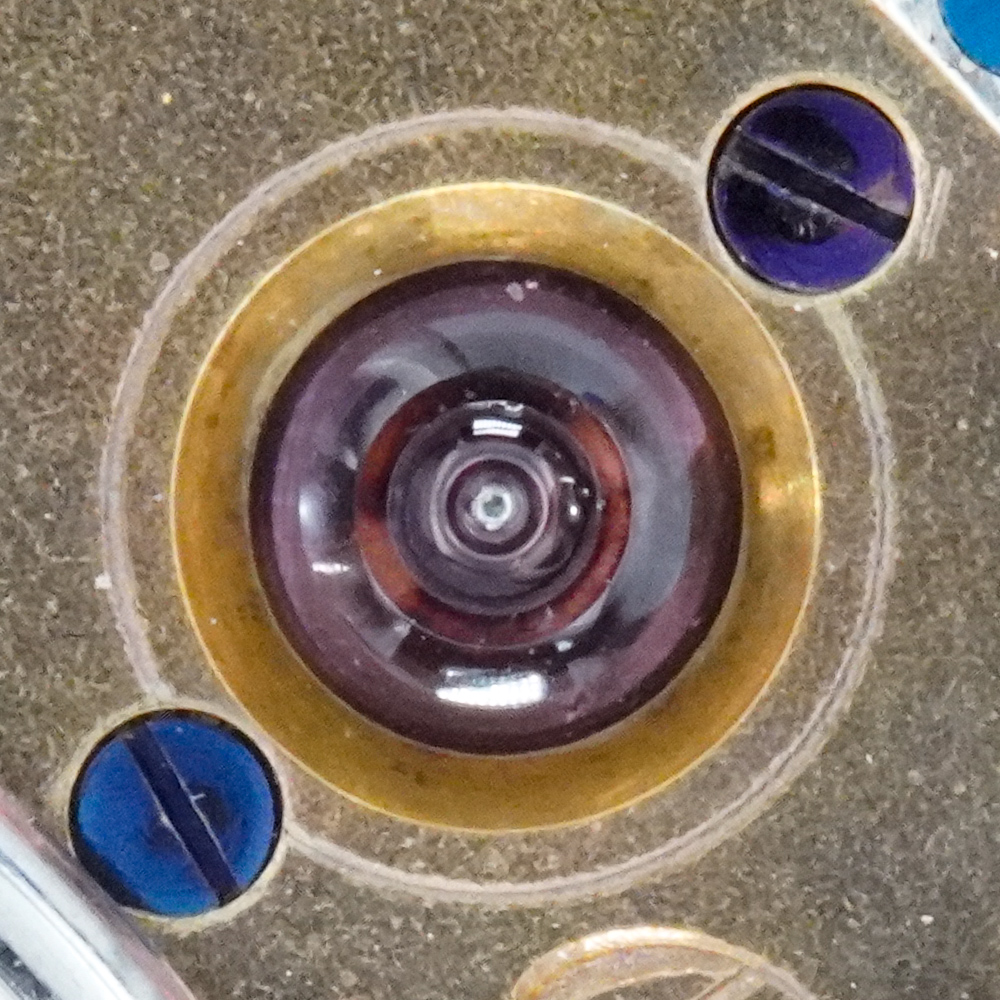

Pictured: A closeup of a screw-set jewel setting.

Screw-Set

Screw-Set jewels are attached to the movement plate with small screws. This required more material and more time to assemble, and as a result, screw-set jewels were commonly fitted into movements of higher quailty. Screw-set jewels are also considerably easier to replace if one is cracked or broken. Premium watches usually contain screw-set jewels settings composed of gold.

Identification: The plate jewel settings are attached by small screws.

Pictured: A closeup of a raised screw-set jewel setting.

Raised Screw-Set

Raised screw-set jewel settings are almost identical to standard screw-set settings except the rim of the setting is raised instead of being flush with the top plate.

Identification: The plate jewel settings are attached by small screws and the setting has a raised rim. The screw heads will not be flush with the plate.