Reference Library

Safety Rollers: Double Roller vs. Single Roller

The primary function of the safety roller is to prevent the escapement from unlocking prematurely due to sudden shock or force while the impulse jewel is disengaged with the pallet fork. If the safety action is not properly adjusted, the impulse jewel can become stuck outside the pallet fork, preventing the watch from operating. While this is commonly referred to as “over-banking,” that particular term actually describes a different issue entirely. Following industry adoption, double rollers were utilized in higher quality movements, including watches intended for railroad service.

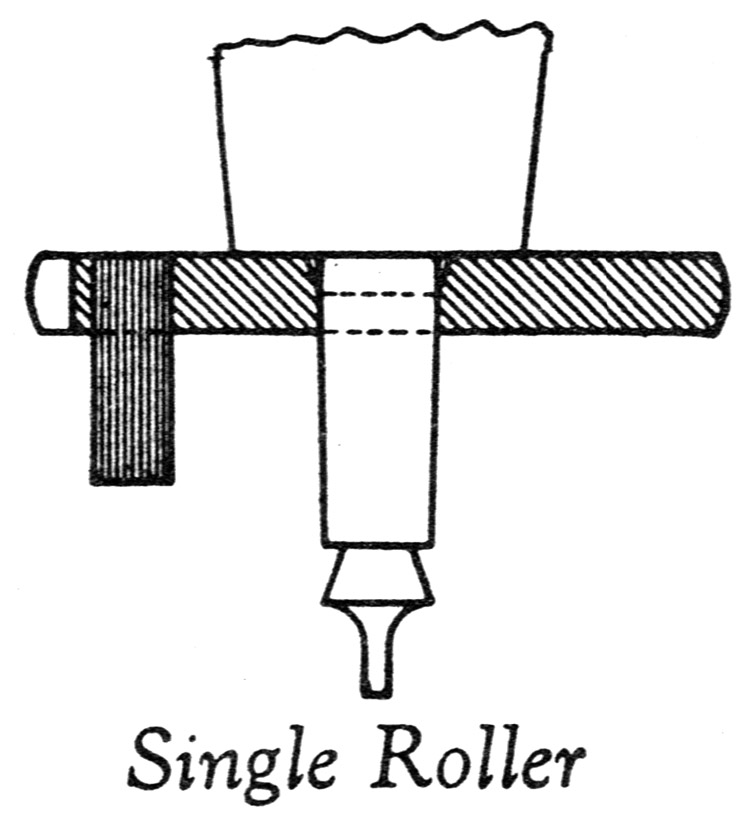

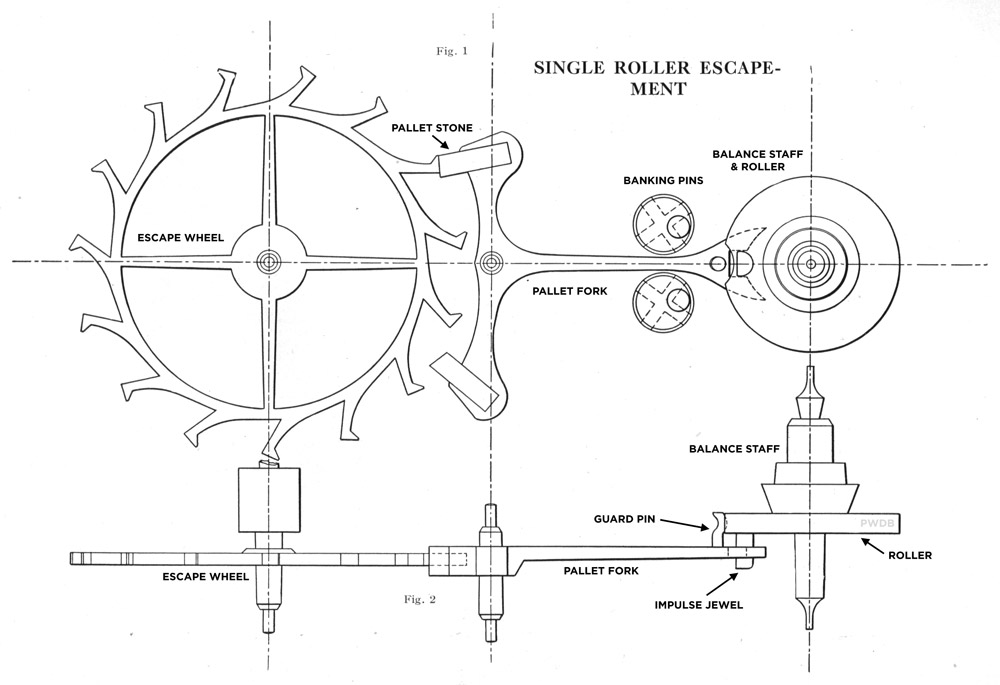

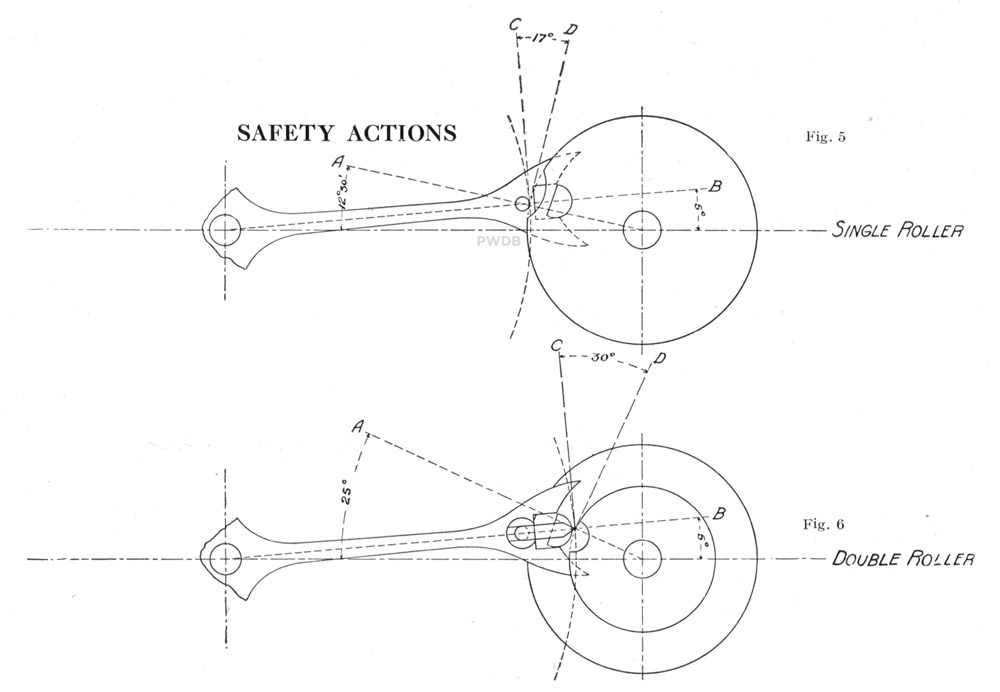

Single Roller

The single roller safety action consists of a guard pin protruding upward from the pallet fork, positioned to be received in a notch at the edge of the roller. As the balance rotates, the impulse jewel becomes disengaged, and the guard pin prevents further movement from the pallet fork until the balance reverses motion and returns with the impulse jewel.

Identification: The guard pin will protrude upward from the pallet fork. A single roller table will be fitted to the balance staff.

Pictured: Diagram of Single Roller from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

Pictured: Diagram of Single Roller from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

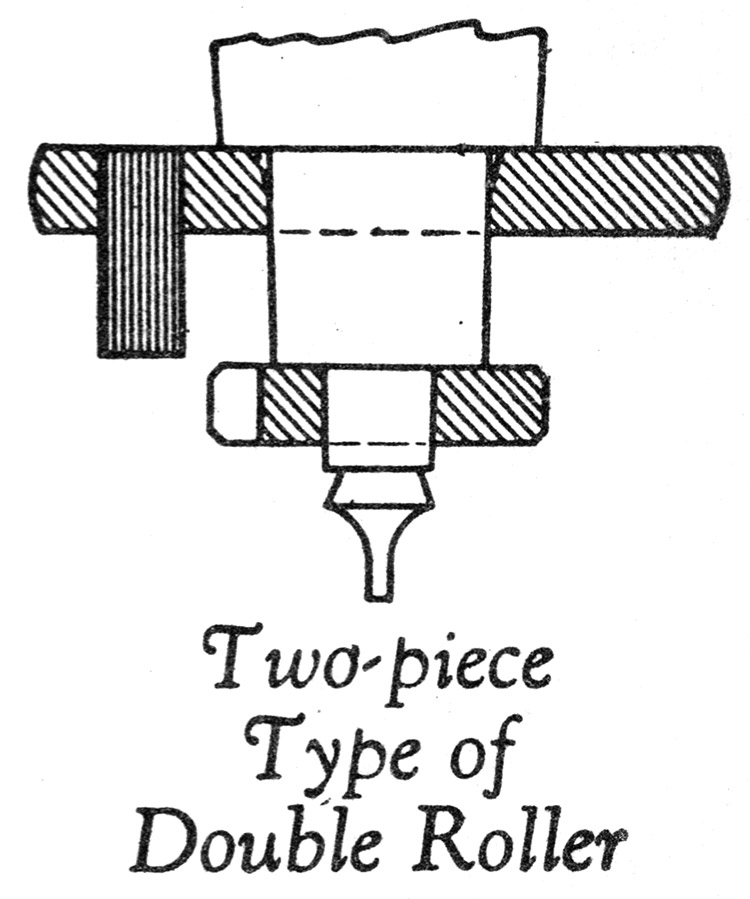

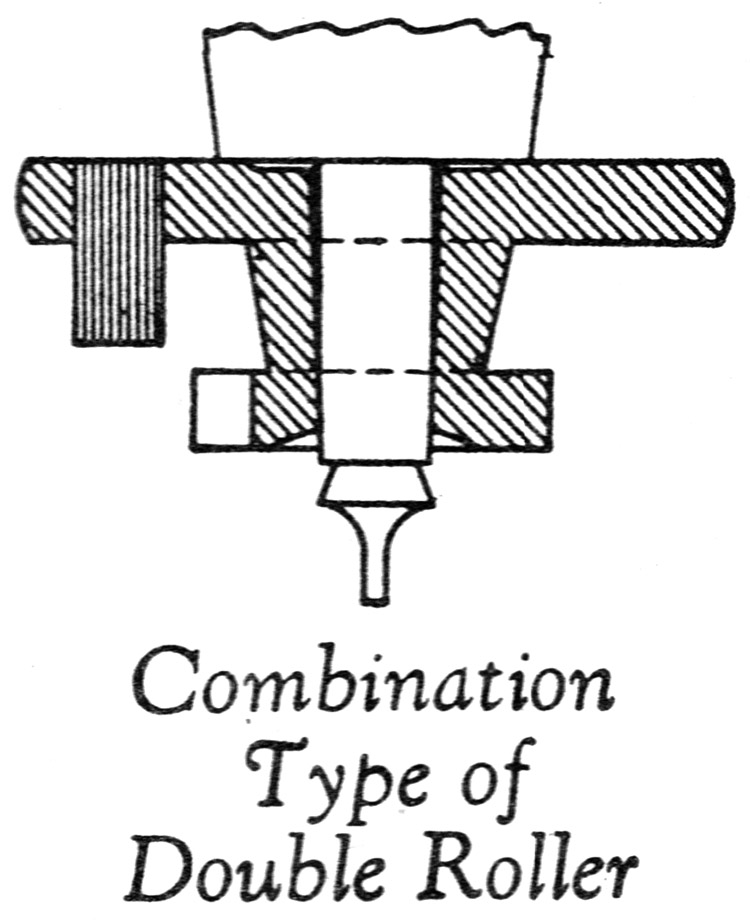

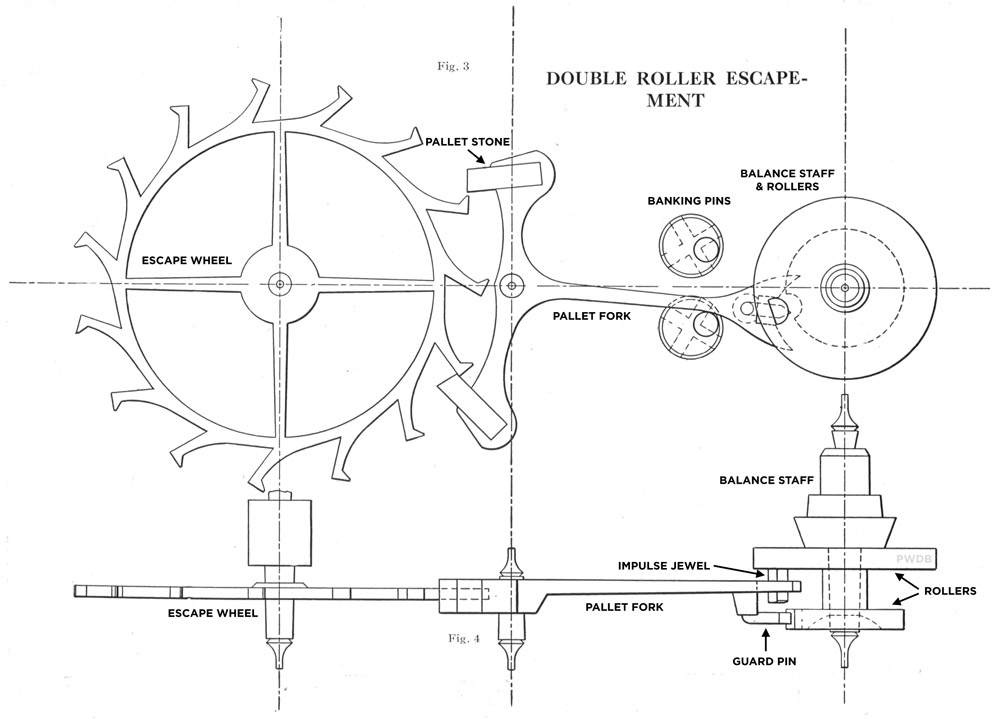

Double Roller

The double roller safety action consists of a guard pin protruding parallel from the pallet fork, positioned to engage a smaller roller located below the primary roller table. This arrangement allows a more efficient engagement between the guard pin and the roller since the roller is of much smaller diameter. As the balance rotates, the impulse jewel becomes disengaged, and the guard pin prevents further movement from the pallet fork until the balance reverses motion and returns with the impulse jewel.

Identification: The guard pin will be parallel to the pallet fork. Two rollers will be fitted to the balance staff.

Pictured: Diagram of Double Roller from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

Pictured: Diagram of Double Roller from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

Pictured: Comparison of Single Roller vs. Double Roller Action Angles from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

Pictured: Comparison of Single Roller vs. Double Roller Action Angles from Helpful Information for Watchmakers (Olaf Ohlson, Waltham Watch Company, 1918).

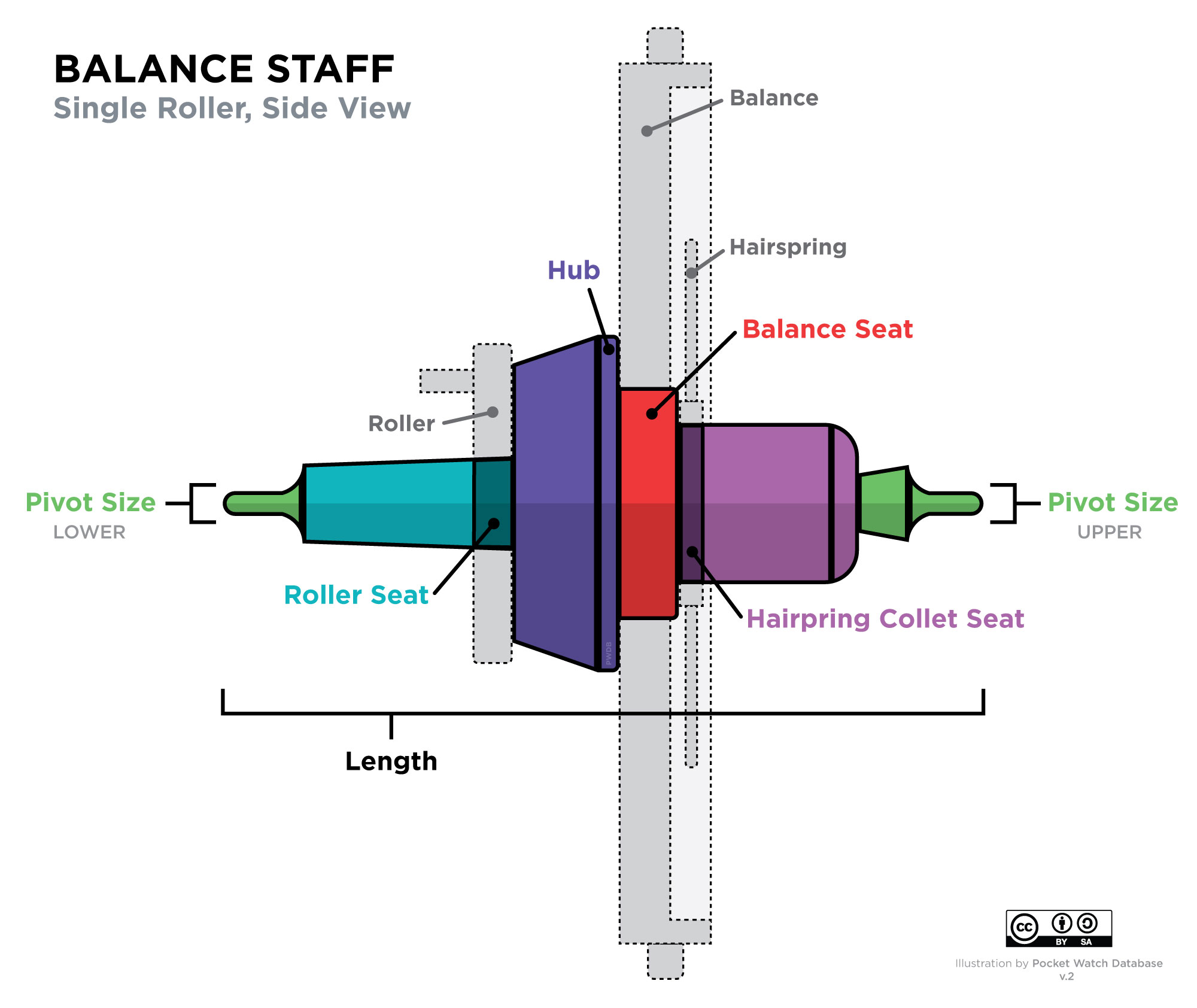

Pictured: Single Roller Diagram (Created by Nathan Moore).

Pictured: Single Roller Diagram (Created by Nathan Moore).